Equipment such as flotation makers, ball mills, jaw crushers, and more play vital roles in the removal and handling of minerals. The flotation machine, for instance, is utilized to separate important minerals from ore, making use of the concept of hydrophilicity and hydrophobicity to assist in splitting up.

Similarly vital is the ball mill, an important part in mineral handling and grinding. This machine carefully grinds products by turning a cylinder with grinding media, generally steel balls or poles. Ball milling has actually verified vital for achieving the preferred particle size in numerous minerals, consisting of copper and gold. Its efficiency in breaking down huge bits and achieving consistent dimension distributions plays a key duty in the succeeding flotation stages, as well-prepared bits yield greater recuperations and qualities.

Jaw crushers stand as one of the main devices in the crushing phase of ore handling. The firmness and sturdiness of materials determine the specific setup of the jaw crusher, ensuring that it can efficiently fulfill the demands of various application kinds, ranging from quarries to reusing plants.

Adhering to the jaw crusher in the process chain is the impact crusher, frequently utilized for second and tertiary crushing. One of the significant advantages of impact crushers is their ability to create top notch accumulations, many thanks to their carefully tuned style that develops cubic-shaped results, lowering the need for additional processing.

In modern aggregate production, sand making equipments have actually tackled a pivotal duty. As the need for high-grade made sand proceeds to expand, these equipments aid in the manufacturing of sand from rocks and crushed rock, substantially boosting worldly high quality. Sand making makers make use of upright shaft impact modern technology, bring about the manufacturing of well-graded, regular fragments. With advancements in technology, these devices have become more effective, enabling operators to optimize making use of raw materials while reducing waste.

Cone crushers are an additional vital tool in the crushing process, particularly when managing high-capacity procedures. Created to take care of hard and abrasive materials, cone crushers make use of a combination of compressive and shear forces to squash material. Their durable layout and progressed technology enable higher throughput and performance, driving down procedure costs while still giving reputable output, necessary for meeting the needs of various tasks.

After the crushing and sizing procedures, sand washing makers come into play. These makers are important for boosting the quality of sand by getting rid of pollutants such as silt, clay, and dust. By employing numerous washing and screening strategies, sand washing machines generate cleaner sands that not only boost quality yet additionally enhance the durability and toughness of concrete and other products. Their function is critical in aggregate processing, as high-grade products are important to the construction market.

Recently, the mobile crusher has gotten acknowledgment for its adaptability and benefit. This mobile equipment allows drivers to crush and process products on-site, dramatically reducing transport prices and enhancing flexibility in operations. Suitable for quarries, building and construction sites, and even recycling jobs, mobile crushers included various setups customized to details crushing applications. Their ability to operate in different atmospheres, combined with technical innovations, placements them as a vital tool in modern aggregate processing.

Commonly consisting of different types of crushers and screens, a well-designed crushing plant maximizes performance and makes sure the efficient processing of raw materials. By integrating tools like jaw crushers, impact crushers, and cone crushers, a crushing plant can adjust to altering conditions while consistently supplying premium products.

Along with these necessary devices, drying systems additionally play an important duty in handling operations. A rotary dryer is one such machine that promotes the removal of dampness from numerous materials, which is crucial in markets where product top quality and service life rely on wetness levels. By effectively drying products, rotary dryers boost the functionality of minerals click here and accumulations and prevent issues associated with storage space and handling.

This operationally basic yet reliable item of devices is widely made use of in artisanal and small mining. The use of the wet pan mill streamlines the removal process while keeping optimal efficiency, making it an appealing alternative for developing regions.

Roll crushers, while commonly overlooked, also play a considerable duty in mineral processing. Their ability to squash materials utilizing rubbing and compression makes them suitable for various applications where consistent size and granulation are necessary. Roll crushers give a controlled and constant result, making them highly advantageous in markets that need details fragment dimension circulations.

As we explore the interconnected roles of these devices in mining, it ends up being clear exactly how each tool adds to the bigger process of resource extraction and production. The best mix of makers, appropriately run and kept, can dramatically enhance efficiency, minimize functional prices, and boost the total top quality of completion items. As sectors remain to evolve and introduce, the dependence on innovative equipment in mining and accumulation handling reveals no indications of subsiding. Accepting developments in modern technology while making certain lasting techniques will certainly be vital as we browse the complexities of resource management in the coming years.

Development in equipment modern technology has actually likewise led to the growth of automation and tracking systems that enhance functional performance. Real-time data evaluation allows operators to make improvements machine performance, optimize operations, and reduce downtime. Such advancements are critical, particularly in environments where every min counts and operational costs are very closely kept an eye on. Industry gamers are increasingly spending in sophisticated systems that allow for anticipating maintenance, lowering unanticipated malfunctions that can disrupt the fragile balance of mining procedures.

Moreover, the ecological impact of mining and aggregate processing can not be disregarded. Striking an equilibrium in between productivity and sustainability has actually become a focus location for many business. Reliable machinery like sand washing devices and flotation equipments aid in maintaining ecological standards by creating top notch materials while reducing waste. The fostering of greener practices and innovations not only enhances conformity with laws but likewise improves a firm's reputation, an important aspect in today's market landscape.

Consistent improvements in products science and engineering also promise to enhance the resilience and effectiveness of machinery. New materials that stand up to deterioration much better can substantially lengthen the lifespan of crushers, mills, and other devices. This durability equates into expense financial savings over time, making the first financial investment extra tasty for services seeking to improve their functional capacities.

In verdict, the globe of mining and accumulation processing is complicated and diverse. Via the assimilation of numerous makers, from flotation makers to mobile crushers, the industry remains to respond and develop to challenges posed by need, ecological policies, and technological advancements. Each tool serves a vital function within the bigger network of procedures, making sure that resource removal is reliable, ecologically conscious, and financially feasible. As we continue to adapt and introduce to brand-new challenges, the future of mining and accumulation handling promises to be amazing and dynamic, leading the way for ongoing growth and sustainability in the industry.

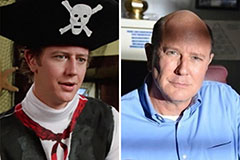

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Barbi Benton Then & Now!

Barbi Benton Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!